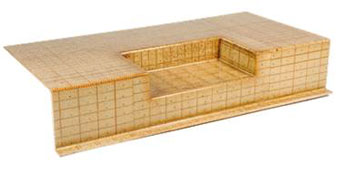

Structural rear step assembly for low-floor bus

Faroex’s variation on Closed Cavity Bag Molding (CCBM)

is typified by a rigid cavity mold with disposable bagging materials or a semi-permanent silicone bag as counter-mold. The cavity mold can be brake-formed and welded steel for non-cosmetic parts or laminated, glass-reinforced, low-profile polyester resin. The laminated mold is balsa reinforced, steel edged, steel framed, with a perimeter vacuum flange. If required, the tool finish can be tooling gel-coat, waxed & buffed to Class “A”. The process is used for infusing very large parts, at a rate of 4 parts per mold per shift. Fabricated steel forms are inexpensive and have a useable life ranging to 1000 parts, depending on geometry. Laminated molds are more expensive but generally have the same life span.

Patented Lightweight 3-D Structural Shear Plates for Commercial Vehicles

Faroex is the leader in large, 3-dimensional, structural shear panels for the transportation, utility, and infrastructure industries. Our unitized sandwich panels provide a level of unmatched flexibility in high-strength component sourcing and design, backed by solid engineering and testing. OEM applications include molded structural floor, roof, and side wall assemblies for leading transit equipment manufacturers. Benefits range from parts consolidation, reduced assembly labor, to weight reduction, with no leaks, and no rot. Aftermarket floor replacement kits – also available from Faroex – are an ideal solution for rotting plywood floors & cracking roof membranes and a cost-effective means of extending the service life of transit vehicles.

You can select from a wide range of core materials to optimize performance, eliminate weight, and control costs:

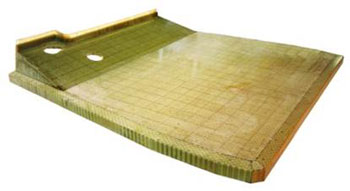

Lightweight, structural floor for Class 7 truck day cab

- High density PVC, SAN, solid and honeycomb PETG, and polyurethane foam cores can be assembled to create complex 3-dimensional shapes such as bus floors complete with integrated wheel housings, step wells, and fuel tank compartments

- Optional end-grain balsa with PVC foam inserts increase screw-holding power

You can also select from a wide range of finishes – standard, smooth natural finish (at right) to sanding gel-coat, ready for paint, or even vacuum-bonded floor covering ready for installation. Faroex’s transit floors pass FMVSS/CMVSS 302 or ASTM E-119.

VARTM lends itself to rapid and cost effective prototyping, with turn around times in the range of 3 weeks from art to part.

Studio

Studio